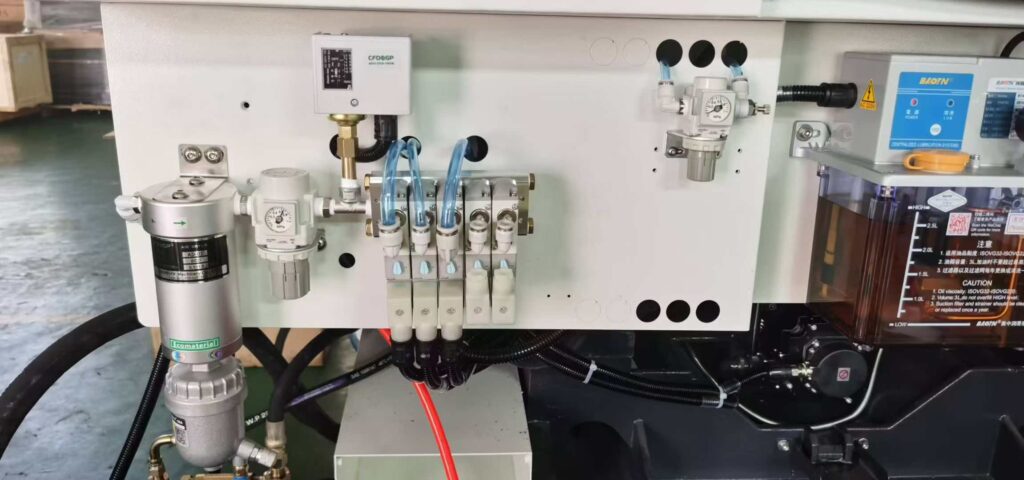

The 4V210-08 solenoid valve manifold is widely used in CNC machine tools. It receives weak electrical signals from the CNC control system (typically a PLC) and converts them into powerful pneumatic actions to precisely control the movement of key auxiliary mechanisms such as the tool changer, clamping devices, and protective doors.

CNC system (PLC/PMC) → outputs an electrical signal (e.g., +24V DC) → solenoid valve driver amplifier (required for high-power valves) → 4V210-08 solenoid valve manifold → controls airflow direction → cylinder.

MOGO’s solenoid valve manifolds are widely used in various machinery, including machining centers, CNC machine tools, and tapping machines.

They are primarily applied in the following six control scenarios:

Action Control: Controls the forward/backward movement of the tool changer for picking up and releasing tools, as well as the rotation/positioning of the tool disk (via a cylinder-driven ratchet mechanism).

Process: The CNC system issues a tool change command → the corresponding solenoid valve coil is energized → the spool shifts → compressed air enters the rodless or rodded chamber of the cylinder → the cylinder piston extends or retracts → completes actions such as tool insertion and removal.

Pneumatic Fixtures: Controls cylinders to drive the clamping and unclamping of jaws.

Process: The operator presses the "clamp" button → the solenoid valve is energized → the cylinder pushes the jaws to clamp the workpiece. After machining, the other end of the valve is energized → the cylinder moves in reverse → the jaws release the workpiece. This is one of the most critical safety functions.

Safety Interlock: Controls the pneumatic locking and release of the machine tool’s protective door. The machine spindle can only start when the door is fully closed and locked, ensuring operator safety.

Process: After closing the door, the valve is energized, and the cylinder locks. When opening the door, the other end of the valve is energized or de-energized (depending on the design), and the cylinder releases.

Center Control: In CNC lathes, it controls the extension of the tailstock center to support the workpiece and its retraction.

Debris Removal: Controls the airflow to the spindle nose or worktable to blow away residual cutting fluid and metal chips before and after tool changes, ensuring precision and cleanliness.

Emergency Stop: In some machine tools, the pneumatic spindle brake is also controlled by such solenoid valves, providing braking during emergency stops or tool changes.

Its characteristics of speed, power, safety (especially the power-off retention feature), and reliability make it an indispensable standard component in modern CNC machine tool automation systems. The main advantages are as follows:

1. Fast Response: The switching speed of the solenoid valve is extremely fast (millisecond level), meeting the demands of high-speed, high-cycle production in CNC machine tools. Tool change time directly impacts machining efficiency.

2. High Power: Compressed air provides sufficient thrust to drive the tool changer and clamp heavy workpieces, offering a more cost-effective and simpler structure compared to all-electric solutions.

3. Safety & Reliability:

Dual-coil Valve Feature: Dual-coil valves have a memory function. Even in the event of a sudden power loss, the spool remains in its last position. This is crucial for clamping systems, preventing accidents where workpieces might loosen and fly off during power outages.

Pneumatic systems offer better tolerance to harsh environments (e.g., oil, moisture, electromagnetic interference) compared to all-electric systems.

4. Simple Structure & Easy Maintenance: Compared to complex electric servo mechanisms, pneumatic systems have a simpler structure, fewer failure points, and are easier to diagnose and repair. The solenoid valves themselves are modular in design and can be directly replaced if damaged.